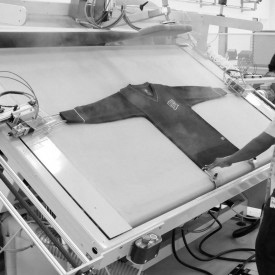

JKPL Knits facility is fully integrated with finishing & QA Control. Delivering quality is something we pride ourselves at Jeans Knit Pvt Ltd. At every stage of the manufacturing process there are strict quality checking procedures and our plant complies to all the policies of SA8000. Modified UPS system (Conveyor Based), first of its kind in the entire world for Post Manufacturing Finishing and Quality Control of Knits & woven Garments. Each conveyor line is a complete module, equipped with its own soft and hard pressing equipment, inspectors, labellers, auditors, and quality control staff. All goods are inspected for manufacturing flaws as well as final measurement. 200 QC and finishing Stations. Modern Quality assurance system integrated with broken needle & Metal detection Machines, ,Automated Finishing operations Ironing, Steaming, Creasing and Folding are achieved from specialized in-house developed Machines. SAP Integrated into the UPS conveyor system, report generation of Quality checks & defects possible for analysis.

All of our finished garments are RFID tagged and validated in SAP at every stage of quality control process, adhering to quality standards as set by the Buyers. Buyer EDI capabilities integrated with SAP pick & Pack module. Automated Conveyor belt lines for packing cartons. Automated Strapping machines to strap the packing cartons Sorted – merchandise Post QC for quality, measurement, size, colour, shade. Generation and updating of packing list through EDI integrated with SAP. Trucking Services – pier pick up – full container.